Tell me a little about yourself!

Tell me a little about yourself!

I am finishing my second year as a PhD student in Chemical Engineering, working under Dr. Gregory Parsons. After I graduate, I would like to work in indsutry in research and development, with the possibility to return to academia somewhere down the line. Outside of the lab, I play intramural soccer, am part of the club swim team, and coach swimming over the summers. I love being outside and meeting new people!

What primary instrument(s) are you using for your research and what do you like about it?

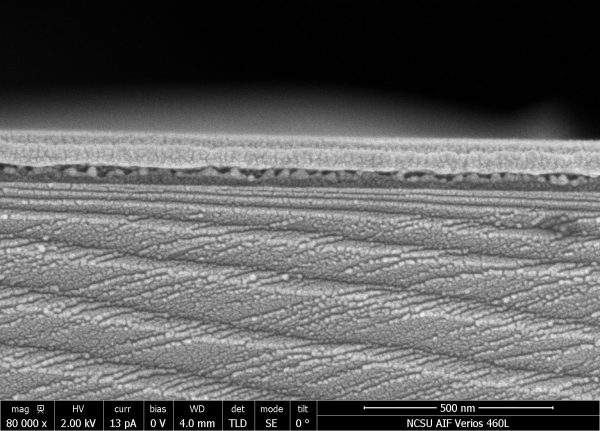

In my research I commonly use the Asylum MFP-3D AFM to analyze the surface roughness of my films, the Rigaku Smartlab X-ray diffractometer for XRR to analyze film density and thickness, and the FEI Verios SEM system to obtain images of my samples. It’s very helpful in my research to have access to so many advanced analytical instruments that allow me to learn more about my samples. Plus it’s nice to get out of the office and enjoy the walk between EB1 and AIF.

What have you been researching?

I work with a thin film deposition technique known as molecular layer deposition (MLD) to deposit and characterize polymer films. This is similar to atomic layer deposition (ALD), except with organic instead of inorganic materials. The organic precursors make this technique a bit more complex, so the actual reaction mechanisms in MLD are not well known. I am working with polyurea films to try to better understand the nucleation and growth mechanisms of MLD processes, enabling them to become more efficient and more industrially available.

How is your research impacting the community?

Thin film coatings are used in so many everyday things, including protective coatings in pipes and automobiles, biomedical sensors, semiconductors for phones and computers, and plenty more. My work specifically is funded by the department of defense, where in addition to understanding MLD growth mechanisms, we aim to understand how the use of polymer coatings can affect energy transfer across interfaces. This fundamental knowledge could advance the field of energetic materials, especially those with military significance (explosive or explosive-inhibiting materials).

What have you learned from your experience at AIF?

Understanding why something doesn’t work is just as important as collecting data when it does. Getting different results (or the lack thereof) at AIF has taught me a lot about the characteristics of my films as well as research in general, and how to collaborate with other professionals.

Best thing about AIF in 5 words or less?

Convenient and very helpful staff

Is there a staff member at AIF that has helped you?

I owe a big thank you to Chuck Mooney, Fred Stevie, BB Chung, and Elaine Zhou for all of the training and help they’ve given me with my research. Thank you all!