Tell me a little about yourself!

I am a fifth-year Ph.D. student in the department of nuclear engineering, working with Profs Jacob Eapen and KL Murty on understanding wear behavior of superalloys for applications in advanced nuclear reactors. I will be graduating in Fall 2020 and currently looking for opportunities in academia, industry, and national laboratories. Outside my lab, I am actively engaging in communication, writing, and leadership training programs at NC State. In my spare time, I like walking and barbecuing with family and friends.

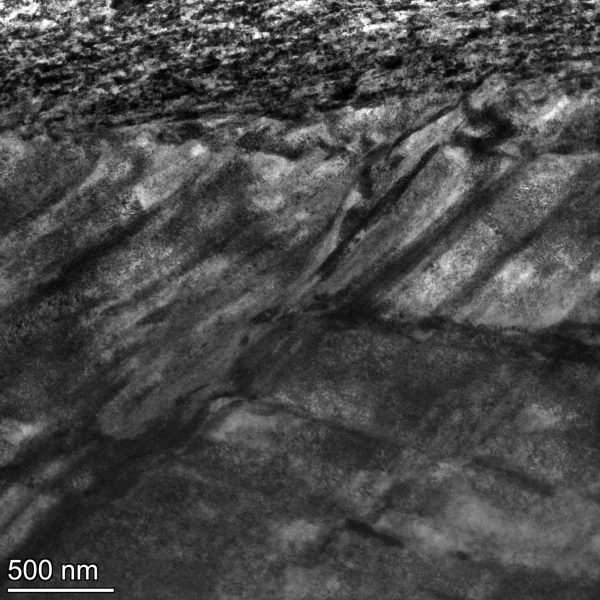

At AIF, I use several instruments, including the FIB-SEM dual beam microscope, Talos TEM, and Verios SEM. I also have completed surface analyses using Raman microscope and Laser scanning confocal microscope. I am eager to conduct further research on ion beam and electron microscopy because of the versatility offered by such advanced instruments. For instance, the complex defect structures in irradiated materials can be investigated using in-situ S/TEM capabilities.

What have you been researching and how is it impacting the community?

The very high-temperature reactor (VHTR) is one of the advanced reactors that are currently being developed. The structural and in-core components of a VHTR operate under extreme conditions. A steam generator is one of the main structural components since its integrity ensures the safe and reliable operation of the nuclear reactor. One of the failure mechanisms of the steam generator is wear that could cause a permanent shutdown of an operating nuclear reactor. For example, the San Onofre Nuclear Generating Station was permanently shut down owing to wear failures of the steam generators in 2013. Two candidate superalloys are proposed for the structural applications of the VHTR, namely Alloy 617 and 800H. During my Ph.D., I study the microstructure evolution of these two alloys under fretting wear conditions in a simulated VHTR environment using advanced materials characterization techniques.

I am focused on understanding the wear behavior of these alloys so that we can develop mitigation techniques to overcome the adverse consequences of wear failures in the current fleet of nuclear power plants as well as in the next generation of reactors.

What have you learned from your experience at AIF?

From my personal learning experience, I would recommend the following:

• New users should seek the basic knowledge of each characterization technique of interest before conducting any experiments. This advice would save time and money later on.

• Starting with the short courses offered by the AIF staff in which users can learn more about the theory and best practices of each instrument.

• Looking for relevant literature on the techniques and the materials under-investigation would help the new users in optimizing the operating conditions for their samples.

• Paying great attention to details while operating the instruments and later in data analysis is crucial for the best experimental outcomes.

• Having a regularly updated Standard Operating Procedure (SOP) in place is very important for achieving efficient performance. A new user is encouraged to seek advice to ensure that the SOP is optimal for his/her samples.

Advanced instrumentation with exceptional user support

When asked what the best thing about AIF is in 5 words or less

Is there a staff member at AIF that has helped you?

It could have taken me much longer to learn these materials characterization techniques without the flexibility and support of the AIF staff. I am grateful to everyone in the AIF. Thanks, Fred, Chuck, Roberto, Chris, Elaine, Phillip, BB, and Anna.