I am a second year PhD student in the Materials Science and Engineering department and works under Dr. Rajeev Gupta. My ongoing project is to understand the corrosion mechanism of Aluminum alloy prepared by high energy ball milling technique. Since corrosion is a surface phenomenon, this work involves the characterization of surface and subsurface region, which is quite fascinating. You get to appreciate the corrosion phenomena at micron and atomic level using electron microscopes like SEM and TEM. Apart from my research world, I love to go to trails, explore yummy new dishes, and do some sketching in my leisure time.

What instruments are you using for your research and why do you like them?

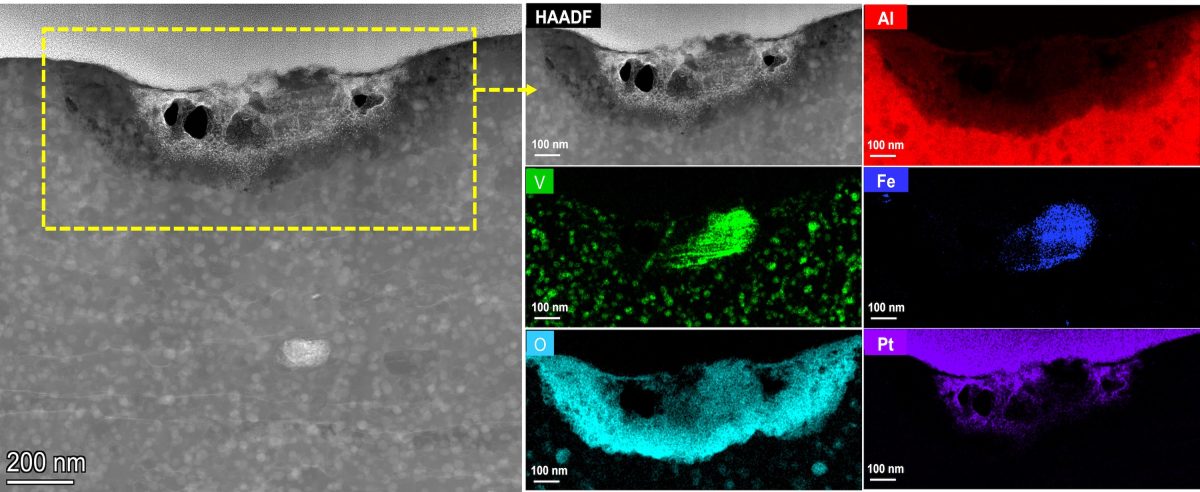

In my research, I use the Talos TEM, FIB, Verios SEM, Rigaku XRD, ToF-SIMS, and XPS. Electron microscopes reveal the stunning images of microstructure where I can understand the nanocrystalline grains, defects, passive film, dispersion of phases, corrosion initiation and much more. ToF-SIMS and XPS answer the modification in chemical composition on surfaces. Using a combination of these instruments will help me to reveal the fundamental mechanism causing the corrosion in Aluminum alloys.

What have you been researching and how is it impacting the community?

Corrosion in metals is seen everywhere around us, and it is an inevitable process. Billions of dollars are spent in either mitigating or delaying this phenomenon. It becomes a huge issue when the applications are related to constructions, marine, aerospace, etc., where the corrosion cannot be tolerated. Imagine a plane carrying many passengers or ship with cargo or a bridge and suddenly there is a premature failure in its components as a result of corrosion. It will be a disaster and loss of many lives and resources. Therefore, researchers are inventing novel materials to enhance the corrosion performance and simultaneously compatible to the application. My research is about discovering the fundamental mechanism to prevent premature failure and will help to open the design opportunities to produce high-strength and high corrosion resistant metal alloys.

My preliminary research is involved with understanding the factors causing the corrosion in conventional Aluminum alloys. The next stage is to figure out how an appropriate alloying element be introduced in it to enhance the performance of that alloy. The final stage involves examining the modification of microstructure and surface by the alloying element that will reveal the mechanism to prevent the corrosion. I have completed the second stage and the final stage is crucial that will answer the role of alloying element in providing the barrier required to inhibit the degradation.

What have you learned from your experience at AIF?

I have learned that we can project the overall picture of corrosion by the fragments of evidence obtained from different individual characterization instruments. AIF has also provided me with limitless resources and knowledge in understanding the basics and operation of instruments.

Best thing about AIF in 5 words or less?

Patient, knowledgeable and friendly staff

Is there a staff member at AIF that has helped you?

I approached Chuck, Fred, Elaine, and Chris for my research and they were super helpful and patient to accommodate my needs. AIF has excellent experts to guide the students in achieving the meaningful outcome from their research.