Ryan Schoell is a 2nd year graduate student who is pursuing his doctorate in nuclear engineering with a minor in materials. His career goals? To one day work for a national laboratory to continue to work on materials research for nuclear applications. Ryan has been a frequent AIF user who is very excited about the research he’s been doing.

What primary instrument(s) are you using for your research and what do you like about it?

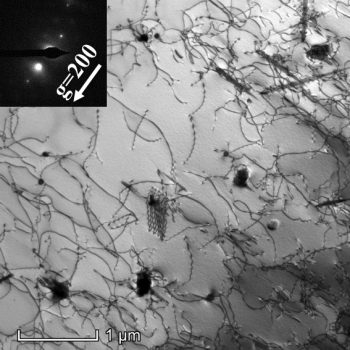

I mostly use the Verios Scanning Electron Microscope, the Focused Ion Beam, and the Talos Transmission Electron Microscope. These instruments allow me the ability to view materials under high magnification as well as the microstructure that govern the materials macroscopic properties. Additionally, these instruments are powerful tools which can be used to characterize the abundance and location of elements as well as determine the orientation of grains inside my material.

What have you been researching?

My project deals with understanding a phenomenon known as stress corrosion cracking which is subcritical crack growth of a material under the influence of both stress and corrosion. My research specifically looks into stainless steel 304 which is used in the waste canisters which hold used fuel from nuclear reactors. Canisters near the coast of the United States are subjected to both residual stress from welding as well as corrosive salts from the marine air. The Department of Energy (DOE) wants to look into the possibility of how cracks could form and how they could propagate under different conditions. If a crack is able to penetrate the walls of the canister due to stress corrosion cracking, the release of radioactive materials into the environment may occur. I use the instruments at AIF to obtain detailed images and chemical maps of the cracks in the sample as well as identify phase changes in the material that may alter the materials cracking susceptibility.

How is your research impacting the community?

I am hoping to gain a better understanding of crack kinetics as well as the factors which effect crack propagation. This type of understanding will allow for better predictions of how and when a canister might fail as well actions that can be taken to prevent the failure of the canister.

What have you learned from your experience at AIF?

My experiences at AIF have taught me both the techniques needed to examine the different aspects of a material as well as more knowledge on the phenomenon of stress corrosion cracking in 304 stainless steel.

Best thing about AIF in 5 words or less?

Knowledgeable and helpful staff

Is there a staff member at AIF that has helped you?

I would like to thank Roberto Garcia, Fred Stevie, Toby Tung, Chuck Mooney, and Yang Liu. All of these staff members at AIF have given me the necessary skills to characterize my test samples and perform good research. They are very knowledgeable and are always able to help students in need.