I am Mostakima Lubna, currently working as a postdoctoral research associate in Dr. Bradford’s research group at Wilson College of Textiles. I have recently completed my Ph.D. in the Fiber and Polymer Science program at the Department of Textile Engineering, Chemistry and Science, under the supervision of Dr. Philip Bradford. My Ph.D. research focused on the design and development of ultra-low-density nanohybrid materials using Carbon Nanotubes (CNTs) and understanding the CNT-polymer hybrid’s architecture at the nano, micro, and macro level to optimize their functionalities in e-textile sensors, and electromagnetic interference (EMI) shielding applications.

I would like to continue my career in research and innovation in the interdisciplinary space of future technological development of advanced functional nanomaterials-polymer-nanohybrids systems either in industry or academia.

Outside research, I love visiting new places, enjoy playing board games, and spending time with friends. I am a big fan of sci-fi novels, TV shows & movies, and also like to watch science and astronomy documentaries.

What instruments are you using for your research and why do you like them?

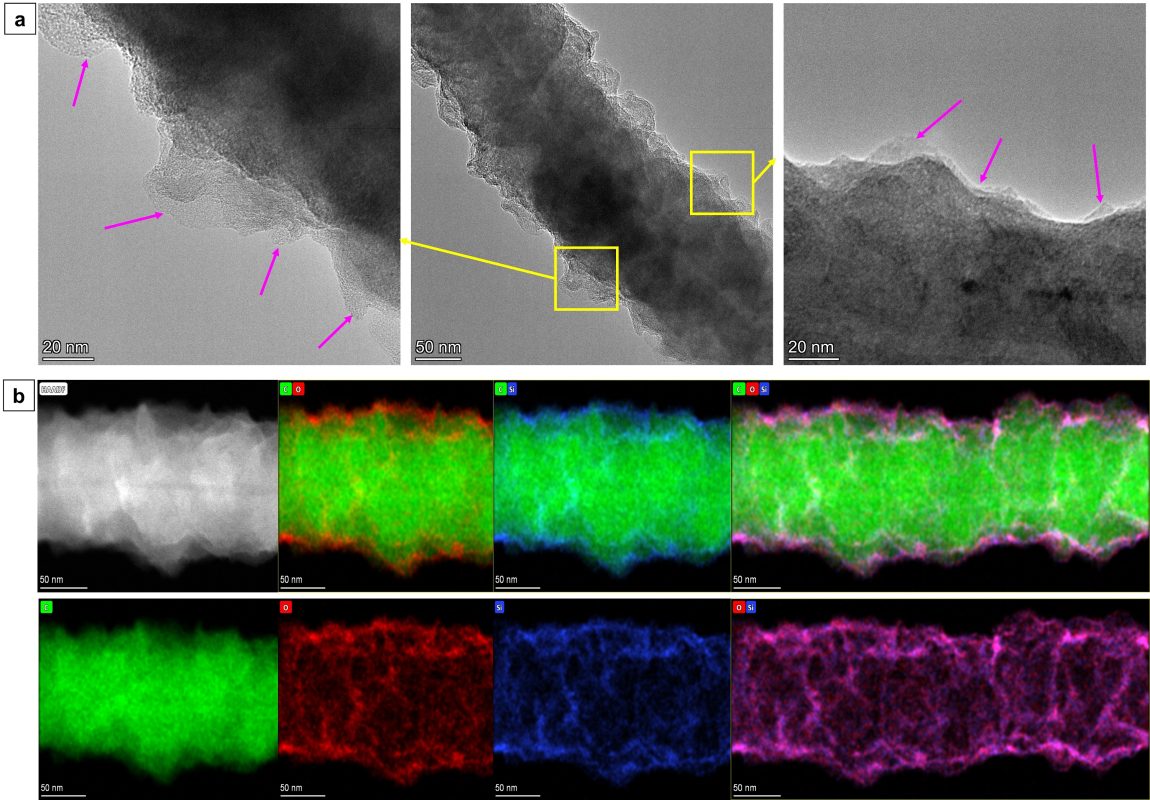

At AIF, I primarily use FEI Verios 460L field-emission scanning electron microscope (FESEM), FEI TALOS F200X transmission electron microscope (FETEM), Horiba Confocal Raman Microscope, and PANalytical Empyrean X-ray diffractometer to understand the structural morphology and composition of the nanohybrid materials for evaluating the surface properties and the process modification effects. These investigations assist in adapting suitable strategies for adjusting the CNT-polymer nanohybrid fabrication methods and help correlate with their respective thermal and electro-mechanical performances.

What have you been researching and how is it impacting the community?

The main focus of my research is to develop ultra-low-density electrically conductive nanohybrids with aligned Carbon Nanotubes (CNTs) and understand the translation of multifunctional nano-properties into the macro or bulk level. We grow very specific spinnable CNTs via the chemical vapor deposition (CVD) technique and fabricate a free-standing 3D architecture with the CNTs by pyrolytic carbon infiltration, followed by the conformal coating of polymers into the CNT scaffolds. For their extraordinary multifunctional properties, CNTs are an ideal candidate for use in many different applications such as sensors, actuators, supercapacitors, EMI shielding, etc. However, translating the nano-properties to the macro or bulk stages along with the handling difficulties of nanomaterials makes them extremely challenging to use in real-life conditions.

Conductive flexible nanohybrid materials have huge implications, especially in wearable electronics, although there are concerns of nano-toxicity in terms of direct exposure of nanomaterials to humans and the environment. The general approach is to incorporate or embed the nanomaterials in a safer matrix material like polymer that prevents the release of nanomaterials in the user environment and stops nano-pollution. But, the incorporation process is happening in the bulk phase, where the problem is bulk matrix materials largely reduce the unique nano functionality. Our innovative design and fabrication approach provides the scope of incorporating a wide range of polymers in CNT nanohybrids for making lightweight, and flexible piezoresistive e-textile sensors. The optimal processing conditions and precise polymer incorporation techniques allow us to tune the CNT nanohybrid design without sacrificing the nano-properties and also ensure proper polymer coatings to avoid nanomaterials release during dynamic use environments. My research will contribute to developing proper nano-incorporation methods in consumer products that will allow us to get the fullest benefits of nanomaterials effectively and safely.

What have you learned from your experience at AIF?

AIF provided me with the practical knowledge of nanomaterials characterization and help me understand the very approach of scientific research by finding the puzzling pieces of nanohybrid materials’ behavior. I believe this experience helped me grow as a researcher.

I have learned various sample preparation and characterization techniques, and can independently operate the Verios SEM and Confocal Raman microscopy.

Best thing about AIF in 5 words or less?

Incredible instruments, amazing staff support

Is there a staff member at AIF that has helped you?

All the AIF staff members I interacted with are very friendly, compassionate, and knowledgeable. As most of my novel nanohybrid samples are ultra-low-density, in many cases we have to find out new approaches for sample preparation and adapt new parameters for analysis. Throughout this “Think and Do” course of action, AIF staff members inspire the learning process and show extraordinary support and patience. Special thanks to Chuck, Chris, Toby, Elaine, Jennifer, and Anna.