My name is Manik Chandra Biswas, a doctoral candidate, working as research assistant at Wilson College of Textiles under the supervision of Dr. Ericka Ford, and a polymer and materials engineer, executed research and product development independently for 7+ years, seeking to develop green biotechnological solution that driving materials innovations as well as their adoption by industry. My research interests are materials engineering, polymer chemistry, fiber spinning techniques, nonwoven textiles, E-textiles, polymer functionalization and modifications, nanomaterials synthesis, and polymer reinforcement.

I like to play volleyball, badminton, soccer, cricket, travel new places, passing time with family and friends.

My dream is to be a future leader and driver in helping the materials and textile industry adopts a circular economy. I would love to work in research and development at any national laboratory or industry and see myself as lead scientist.

What instrument(s) are you using for your research and why do you like it/them?

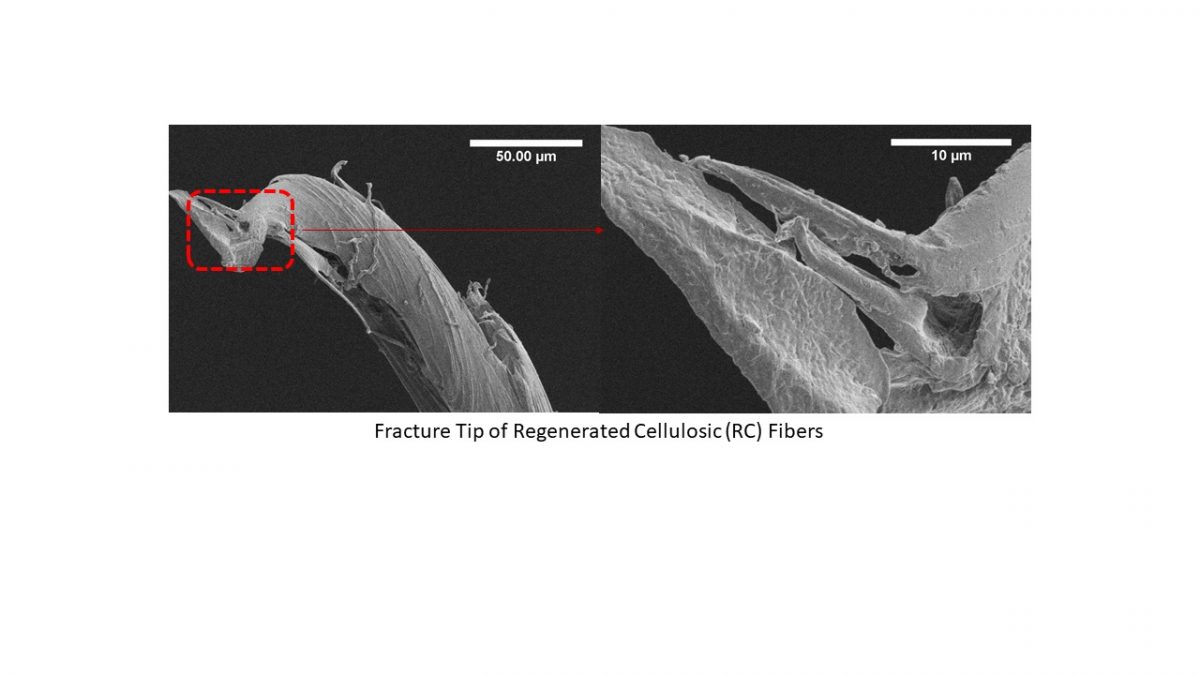

I mainly have been using the Rigaku Smartlab X-ray diffractometer and FEI Verios 460L field-emission scanning electron microscope (FE-SEM) for the analysis of fiber samples, investigating the microstructural changes and failure mode analysis. I like both the instrument as one can get full understanding of any microstructural changes as well as morphological modifications. As we know, XRD is a fascinating tool to understand the crystallinity index, crystal size, lattice structure of any samples and that helped me to correlate the results with structure-processing and consequently the performance. SEM imaging were very helpful to get the insight of the surface morphology of the modified fibers and failure mode analysis of those fibers after tensile test.

What have you been researching and how is it impacting the community?

My graduate research (at Master’s and doctoral levels) focuses on innovations in the conversion of biomass waste into value-added materials and substitution of petroleum-based additives with biomass derivatives for the strengthening of plastics and regenerated fibers from natural resources. Overall, this research will improve the sustainability of the textile industry by introducing overlap between the circular economies of both the textile and agricultural industries.

In recent decades, there has been an explosion of conscientious efforts to improve the sustainability and circularity of textile and fashion brands-related economies. As the global population increases, so has the use of clothing and its waste byproducts. Recent clothing trends has sparked the demand for fast fashion, while spiking the pollution of clothing in landfills. Microfiber pollution in seawater and other waterways is of great concern. Such environmental concerns have caused efforts in sustainability to trends in the textile industry.

This has prompted renewed interest in the use of natural and/or biodegradable fibers as alternatives to petroleum-based synthetics.

My doctoral research focuses on replacing toxic and environmentally harmful additives in clothing known as “cellulose acetate fibers” (which are found in high-quality, dry-clean-only clothing, such as wedding gowns) for stronger, greener fibers. He developed a sustainable clothing fiber spinning technology that is safer and greener when compared to current means, and filed a U.S. patent for this technology and published a peer-reviewed journal article in the journal Carbohydrate Polymers. You can read the published article here: “Glucaric Acid Additives for the Antiplasticization of Fibers Wet Spun from Cellulose Acetate/Acetic Acid/Water.”

The recycling of cellulose from cotton textiles would minimize the use of virgin crop fibers and nonrenewable petrochemicals as sources of resin for synthetic fiber production. Products manufactured from recycled polymers are generally inferior in mechanical performance to those made from virgin resin or natural fibers; this behavior would likely apply to regenerated cellulose (RC) sourced from recycled cellulose. This challenge prompted the investigation of biobased additives that were capable of improving the mechanical strength and stiffness of fibers by means of anti-plasticizing additives.

Best thing about AIF in 5 words or less?

Resourceful, Experts Hub, One-in-One Place, Reliable, Friendly.

Is there a staff member at AIF that has helped you?

All the AIF staff members are very welcoming and helpful. I have been mostly working with Chuck and BB for testing my samples. I have also contacted BB, Elaine, and Anna for other needs throughout my graduate studies and I am really grateful to them for their time and friendly support.